A new class of sensor for visual overhead line monitoring.

Not another DLR system, but a new kind of sensor — one that doesn’t replace existing DLR platforms but enhances them.

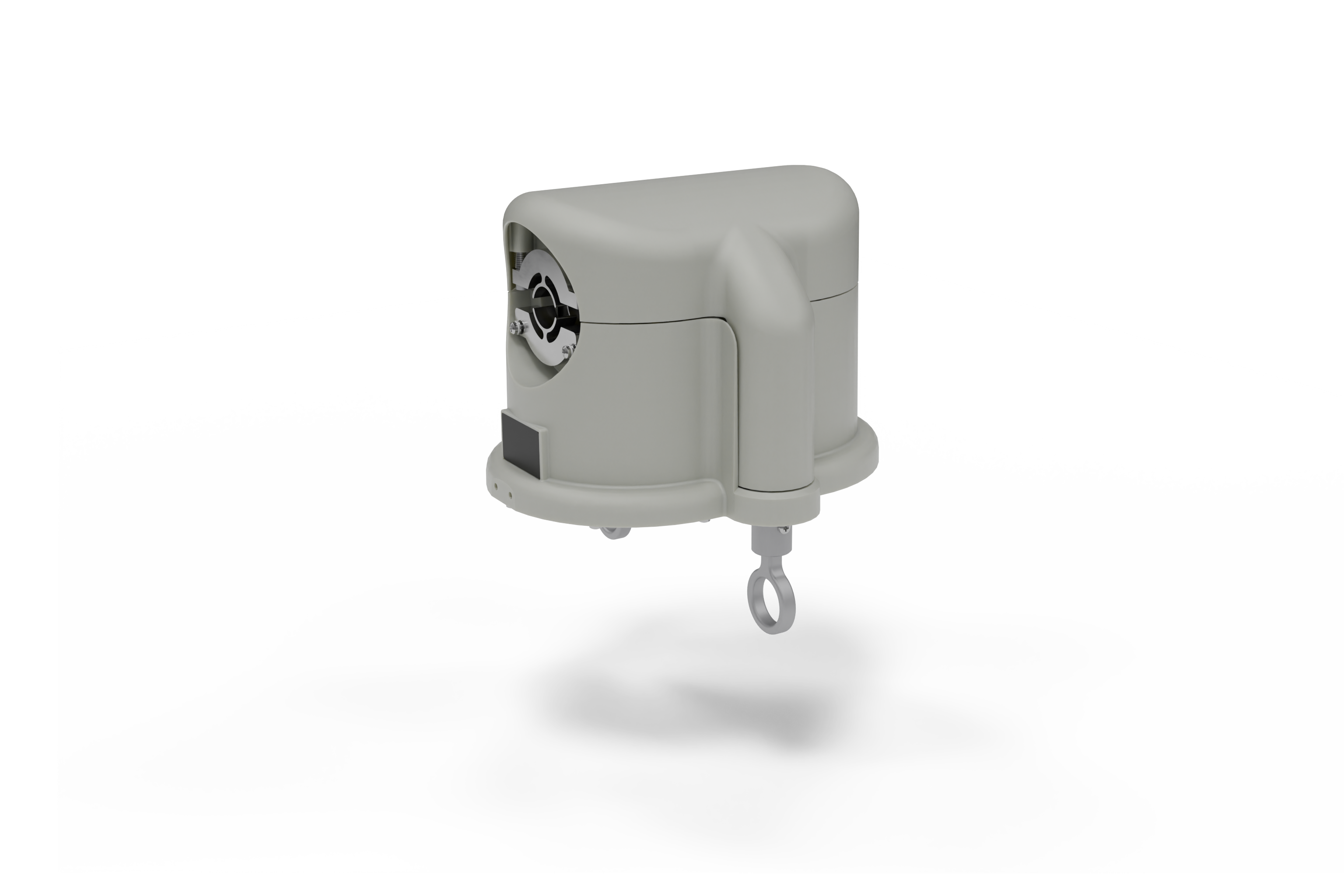

MOL is the first open, interoperable and vendor-agnostic sensor that brings true visibility to the grid: line conditions, environmental context, corridor activity, wildfire risk, ice and anomalies — all in a single device.

Designed for TSOs, DSOs and system integrators who want to go beyond DLR. DLR becomes just one of its outputs, while the real value comes from combining line, environmental and visual data in one open, flexible sensor.

«When every vendor closed the system around DLR, we opened it. MOL brings the one thing the grid was missing: eyes. MOL is the first open sensor that lets the grid be seen, not just measured»

Interested in piloting MOL on critical lines?

In a 30-minute session, we can review your current or planned DLR and grid-monitoring setup, identify priority lines and corridors, define key use cases, assess integration options with SCADA, EMS, DMS or DLR platforms, and outline a pilot and progressive roll-out.

|

|

|

|---|---|---|

| Order Code | MOLHV001 | MOLMV001 |

| Primary focus | Visual + IR monitoring of line & corridor HV line sensing (temperature, ice, galloping, sag) |

MV line sensing: ice, galloping, sag, vibration, pole displacement |

| Target customers | TSOs, DSOs, software vendors, IoT platform developers, system integrators, OEMs and engineering firms | TSOs, DSOs, software vendors, IoT platform developers, system integrators, OEMs and engineering firms |

| Intended use | High-voltage overhead lines | Medium-voltage overhead lines |

| Line Voltage/Current | Up to 420 kV / 20 A – 1.000 A @ 50 Hz | Up to 35 kV / 8 A – 400 A @ 50 Hz |

| Cable diameter | 15 - 50 mm | 7 – 16 mm |

| Material | Die cast aluminum / IP66 | Glass fiber reinforced plastic / UL 94 V2 / IP66 |

| Power / Backup | Inductive AC power / superCAP as backup energy storage | Inductive AC power / superCAP as backup energy storage |

| Visual camera | Yes | No |

| IR camera | Yes | No |

| Line current measurement | Yes | No |

| Cable temperature (PTC sensor) | Yes | No |

| Sag estimation | Yes | Yes (via accelerometer) |

| Vibration monitoring | Yes | Yes |

| Ice detection | Yes (visual + thermal cues) | Yes (mechanical behaviour changes) |

| Wildfire detection | Yes (IR + visual) | No |

| Environmental sensors | Temperature & humidity | No |

| DLR support | Full hybrid DLR (current + sag + temp proxy) | Partial (mechanical insights only) |

| Communication | LPWAN LTE + MQTT | LPWAN LTE + MQTT |

Everything you ever wanted to know about MOL but were afraid to ask.

MOL is a new class of sensor because it changes the role that line-mounted devices can play on overhead power lines.

Traditional sensors are built for one purpose only: Dynamic Line Rating (DLR). Their job is to measure physical conductor parameters and send them to a proprietary software platform designed specifically for DLR.

MOL takes a completely different approach. It is designed first and foremost as a sensor for environmental data, visual imaging and infrared imaging, turning every span into a true observation point. This enables utilities to monitor not only conductor conditions and hardware behaviour, but also the entire corridor — vegetation, wildfire risk, ice formation, anomalies, land activity and more.

Another major innovation is openness. While traditional sensors are tightly coupled to their own DLR software platforms, MOL is an open sensor. It transmits all collected data through standard, interoperable IoT protocols, allowing it to integrate directly with existing DLR platforms, SCADA/EMS/DMS systems, IoT platforms, analytics tools and any third-party application — without forcing the adoption of a new closed ecosystem.

In short: MOL is not just another DLR sensor. It is the first open, visual and multi-scenario device designed for TSOs, DSOs, software vendors, IoT platform developers, system integrators, OEMs and engineering firms who need a broader and more actionable view of the grid.

MOL is an open sensor because, unlike traditional line-mounted devices, it does not lock utilities into a proprietary software ecosystem. Conventional DLR sensors are tightly bound to the vendor’s own platform — meaning the hardware is only fully usable if the utility adopts that specific DLR system.

MOL takes the opposite approach. It is built from the ground up to be interoperable, vendor-agnostic and platform-neutral. All data it collects — visual, infrared, line-behaviour and environmental — is transmitted using standard, well-documented IoT protocols (such as MQTT over LPWAN LTE). This ensures:

- Secure and controlled access to the data

- Direct integration with any existing DLR platform

- Compatibility with SCADA, EMS, DMS, IoT platforms and analytics tools

- Freedom for TSOs, DSOs and system integrators to use MOL within their preferred architecture

- No requirement to install a new proprietary software stack

In practical terms, calling MOL “open” means that utilities own their data, choose their platforms, and keep full flexibility — while still gaining the benefits of a sensor that supports DLR and many additional use cases.

In short: MOL is “open” because it delivers all its data through secure, standard IoT protocols — allowing TSOs, DSOs and integrators to use it with any platform, without vendor lock-in or proprietary software. It gives full flexibility, full ownership of data, and seamless integration across existing grid systems.

Yes — MOL is not just innovative; it represents a patent-pending, next-generation approach to overhead line monitoring.

Unlike traditional DLR-centric devices, MOL defines a new class of open, visual, multi-scenario sensors that pair line measurements with dual imaging (visible + IR) and fully vendor-agnostic data integration. This extends monitoring far beyond DLR to include wildfire detection, ice formation, corridor surveillance and environmental observation.

MOL also features a patent-pending machine learning system that optimizes sensor functionalities based on the real-time energy available on the line, ensuring reliable operation even at low currents while maximizing imaging, sensing and communication performance.

In short: MOL is an innovative, patent-pending sensor that combines line measurements, visual + IR imaging and open data integration — enabling many use cases beyond DLR. Its ML-powered energy optimization makes it a next-generation solution for overhead line monitoring.

Absolutely YES. MOL can collect the key measurements required for Dynamic Line Rating (DLR), but it is not limited to DLR the way traditional sensors are.

Conventional devices are designed primarily — and sometimes exclusively — to measure physical line parameters for DLR. MOL, instead, is built as a multi-purpose, visual and environmental monitoring sensor that also supports DLR when needed.

MOL can provide the core inputs used for DLR calculations, including:

- Sag

- Line current

- Conductor-temperature proxies

These measurements are delivered through secure, open IoT protocols, making them compatible with any existing DLR engine, whether cloud-based or on-premise. MOL does not force the use of a proprietary software platform — utilities remain free to keep using their current DLR systems.

But where MOL truly differentiates itself is in what it provides in addition to DLR:

- Visual monitoring (visible + IR)

- Wildfire early detection

- Ice / frost / snow detection

- Corridor and asset surveillance

- Environmental and land monitoring

- Anomaly detection and situational awareness

In short: MOL is fully DLR-ready, but it is not just another DLR sensor. It collects DLR data as one of its outputs, while delivering a much broader and more strategic view of the grid and its surroundings.

Yes. MOL continuously gathers environmental information through its integrated visible-light camera, which features a 3.3 mm focal-length lens and a wide 103° field of view (customizable as required). In its standard configuration, the camera captures 720 × 480 images at 96 dpi, providing operators with clear visibility not only of the line itself but also of the entire corridor around it.

This imaging capability helps detect conditions that affect the line — such as ice formation, galloping, fallen objects and hardware anomalies — while also monitoring critical components like insulators, clamps and surge arresters. At the same time, MOL provides real-time situational awareness of the broader environment, enabling the identification of vegetation encroachment, corridor changes and early indicators of wildfire risk.

In short: Yes — MOL captures environmental data by visually monitoring the entire corridor, offering wide-angle insight into line conditions, hardware status, vegetation, anomalies and wildfire risks.

Yes — MOL’s infrared (IR) camera provides thermal information that extends beyond the conductor itself, offering valuable insight into the surrounding environment.

Equipped with a 56° field of view (FOV) and a 160 × 120 resolution at 96 dpi, the IR sensor can detect abnormal heat patterns not only on the line and its hardware, but also in the nearby corridor. This enables early identification of potential wildfire hotspots, overheating components, thermal anomalies in vegetation, and other conditions that may pose a risk to grid reliability or safety.

In addition, IR data can be correlated with visible-spectrum imaging and other sensor measurements to improve redundancy, support “virtual sensing,” and enable more accurate interpretation of environmental and asset conditions.

Note: As with any thermal imaging system, accuracy can be influenced by reflections and emissivity variations on surfaces. In some cases, conductor coatings or other surface treatments can further improve measurement consistency.

In short: Yes — MOL’s IR camera provides thermal awareness of both the line and its environment, supporting early detection of hotspots, anomalies, and wildfire risks, even at night.

MOL works as an open, interoperable sensor that collects valuable line, environmental and visual data — and delivers it securely to the platforms you already use. It does not include a proprietary backend or DLR engine; instead, it enhances existing systems by providing richer, high-quality inputs.

We operate with a simple assumption: the real experts of the grid are the people who own and run it — TSOs, DSOs, and their technology partners. MOL is built to empower them, not replace them.

1. Data Collection

MOL gathers a wide set of measurements directly from the span, including:

- sag

- line current

- conductor-temperature proxies

- ambient conditions

- visible + infrared

- imaging of the line and corridor

This turns each span into a real-time observation point supporting DLR, surveillance, wildfire detection, ice monitoring and more.

2. Secure Data Transmission

All data is sent in near real time using secure, standards-based IoT protocols (e.g., MQTT over LPWAN LTE). No proprietary gateways, no closed ecosystem — utilities keep full control and ownership of their data.

3. Analysis is done by your existing platforms

MOL does not process or interpret the data. Analysis — including DLR calculations — is performed by your current SCADA, EMS, DMS, DLR platforms, or by third-party IoT and analytics systems.

In short: MOL collects line, environmental and visual data and delivers it securely via open IoT protocols to the platforms utilities already use. It performs no analytics itself — instead, it feeds SCADA, EMS/DMS, DLR engines and IoT platforms with richer, real-time inputs, letting grid experts stay in full control.

No — MOL does not include a proprietary DLR software platform, and this is by design.

MOL is an open, vendor-agnostic sensor that delivers high-quality line, environmental and visual data through standard IoT protocols (MQTT over LTE/LPWAN), so it can integrate directly with any existing DLR engine, SCADA, EMS, DMS or IoT platform.

We believe the true experts in grid operation are the utilities and the platform providers they already trust.

Instead of forcing a new closed ecosystem, MOL is built to feed those systems with reliable, real-time data — not replace them.

MOL is DLR-ready, but platform-neutral. It works with the tools you already use.

In short: MOL does not include its own DLR platform — it simply feeds any existing DLR or grid system with high-quality data. It’s DLR-ready, platform-neutral, and designed to work with the tools utilities already trust.

MOL uses open, modern and industry-standard IoT communication protocols, making it easy to integrate with any existing grid platform or DLR software.

MOL communicates through:

- MQTT over secure transport (TLS) — lightweight, encrypted and reliable for real-time IoT data delivery

- LPWAN LTE (e.g., LTE-M) — wide-area cellular connectivity designed for remote overhead lines

- An open data model that maps easily into OT protocols such as IEC 60870-5-104 or IEC 61850 via standard IoT–OT gateways

This design ensures secure, interoperable and vendor-agnostic integration with SCADA, EMS, DMS, DLR engines, IoT platforms and analytics tools — without requiring proprietary software or custom interfaces.

In short: MOL uses open protocols to integrate seamlessly into any grid architecture.

MOL integrates easily into existing grid architectures because it uses open IoT protocols and a vendor-agnostic data model.

All measurements — including sag, temperature proxies, vibration, current, environmental data and diagnostics — are published via MQTT over TLS to an IoT broker.

From there:

- Any DLR platform can subscribe to the relevant MQTT topics and ingest the data directly, without custom interfaces.

- IoT–OT gateways can map the same data into SCADA, EMS or DMS using standard OT protocols such as IEC 60870-5-104 or IEC 61850.

Since MOL does not require or impose its own backend, it fits naturally into both current infrastructures and future architectures, allowing utilities, integrators and platform vendors to build on the systems they already trust.

In short: MOL integrates everywhere — because it is open by design.

MOL’s data transmission interval is configurable and depends on the application requirements and the real-time energy available on the line.

Typically:

- Measurements are sent every few minutes (e.g., 5-minute cycles), matching common DLR and grid-monitoring workflows.

- If used with a DLR engine, ratings can be computed at the same interval by the receiving platform (MOL does not perform the calculation itself).

MOL also includes a patent-pending machine-learning system that optimizes sampling and communication frequency based on available harvesting energy. When line current is low, the device automatically reduces transmission to preserve power while still maintaining essential monitoring.

In short: MOL adapts its reporting rate intelligently — frequent when needed, efficient when energy is limited.

Yes. MOL sensors can be relocated to a different line or span when operational needs change. The only requirement is to replace the clamp rings so they match the diameter of the new conductor.

Relocation is generally straightforward; the only limitation may arise if the new line has significantly different current levels, which could affect available harvesting energy. Apart from this, MOL devices are designed to be redeployed as assets evolve.

In short: MOL is fully reusable and can follow your grid priorities over time.

MOL is designed so that a temporary loss of power or communication does not immediately compromise grid operations.

First, each MOL device includes an onboard supercapacitor backup (superCAP) that can keep the sensor running when harvested line energy is not available (for example during very low current or short outages). During this time, measurements and communication can continue without interruption.

If, after this buffer, a MOL sensor still cannot operate or communicate, your existing DLR and grid-monitoring logic takes over. Because MOL is platform-neutral, the backup strategy is implemented on the utility or platform side, typically by:

- Using data from other MOL sensors or other instrumented spans still online.

- Falling back to weather-based or model-based DLR estimates, already implemented in the DLR platform or utility backend.

- Applying conservative static or seasonal ratings where required for safety.

In short: MOL has local resilience thanks to its superCAP backup. Beyond that, your existing DLR/SCADA/EMS/DMS platforms continue operating using their own fallback models, ensuring safe and continuous operation even if a single sensor goes offline.

No. MOL does not use internal batteries. This is a deliberate design choice to avoid battery degradation, reduce maintenance requirements and ensure long operational life.

Instead, MOL relies entirely on inductive energy harvesting from the line. To handle temporary drops in line current, the device is equipped with a supercapacitor bank (superCAP) that provides energy for autonomous operation. This allows MOL to continue measuring and transmitting data during short low-energy periods without interruption.

If the line current remains too low for an extended time, the device simply pauses communication to preserve energy — it is not damaged — and automatically resumes normal operation once harvesting conditions improve.

In short: MOL is battery-free, maintenance-free and designed to operate reliably for years using harvested energy and supercapacitor buffering.

The exact minimum current depends on the line characteristics, but as a general guideline MOL can begin powering its essential functions at approximately 20 A. Above this threshold, the system harvests enough energy to operate sensing, imaging and communication reliably.

At very low currents, MOL may temporarily reduce or pause non-critical functions such as data transmission to conserve energy. This does not damage the device: it simply waits until harvesting conditions improve and then automatically resumes normal operation.

It’s also worth noting that DLR is only meaningful at higher current levels, typically on congested or heavily loaded lines — conditions under which MOL’s energy harvesting works optimally.

In short: around 20 A is sufficient to start basic operation, with the sensor adapting intelligently to energy availability.

MOL delivers the greatest value when installed on critical or high-priority overhead lines where enhanced visibility can prevent issues or improve operational decisions. Typical candidates include lines affected by:

- Congestion or high loading, where real-time monitoring supports DLR and operational flexibility

- N-1 scenarios, requiring preventive redispatch or topology adjustments

- High penetration of renewable or distributed generation, where variability impacts line behavior

- Interconnectors or bottleneck corridors, where small gains in capacity or awareness deliver large system benefits

- Safety or compliance risks, such as clearance issues or ageing infrastructure

- Remote or hard-to-access areas, where vegetation management and inspection are challenging

- Forest or rural regions with elevated wildfire risk, where early detection is critical

In short: MOL should be deployed on the lines where real-time visibility can reduce risk, prevent outages and improve operational flexibility.

MOL can be installed on all common overhead line conductor types, as long as the surface is electrochemically compatible with aluminium. This includes:

- ACSR

- AAC

- AAAC

- AMS

- And similar aluminium-based conductor families

Each MOL unit is equipped with a dedicated EPCM adaptor ring and a matching metallic clamping ring selected according to the specific conductor diameter and material. For copper conductors, MOL can also be installed using specially designed adaptor rings that ensure proper mechanical and electrochemical compatibility.

In short: MOL is compatible with virtually all standard overhead conductors, provided the correct adaptor ring is used.

A span is considered critical when its conditions can significantly affect operational safety or monitoring effectiveness. Criticality is influenced by factors such as:

- Span orientation and exposure to wind

- Local wind-screening effects caused by terrain, vegetation or nearby structures

- Obstacles such as buildings, roads, rivers or forested areas

- Vegetation growth that may approach clearance limits

- Wildfire-prone corridors where early detection is valuable

Open, obstacle-free fields are generally less critical. As a guideline, installing one or two devices per line section, or roughly one sensor every 3–10 km, provides effective coverage for most use cases — from DLR support to surveillance and wildfire monitoring.

In short: critical spans are those where visibility and monitoring matter most, due to environmental, structural or safety factors.

MOL is typically installed near the tower, usually 1–2 meters from the insulator, and always on a bare, uncoated section of the conductor. This position provides the most reliable conditions for measuring sag-related parameters and ensures stable imaging of the corridor and hardware.

Installing MOL closer to the center of the span is not recommended, as it reduces the sensitivity and relevance of line-behavior measurements and may limit the stability of visual monitoring.

In short: MOL should be mounted near the tower on an exposed conductor segment for optimal sensing and imaging performance.